Our quality department ensures the control and conformity of all the parts we produce, regardless of the production process used. We have strict control procedures to ensure that the parts meet your specifications. By ensuring that your parts meet your expectations, we help you to reduce your costs by reducing the number of iterations.

Our quality control (QC) department ensures that the standards in force are respected, for example a temperature of between 18°C and 22°C and a controlled humidity, in order to guarantee the accuracy of the dimensional measurements carried out.

We attach great importance to the quality and conformity of the parts we produce. This is why we have put in place a rigorous control procedure in two inspection phases:

Our latest quality generation and dimensional inspection machines:

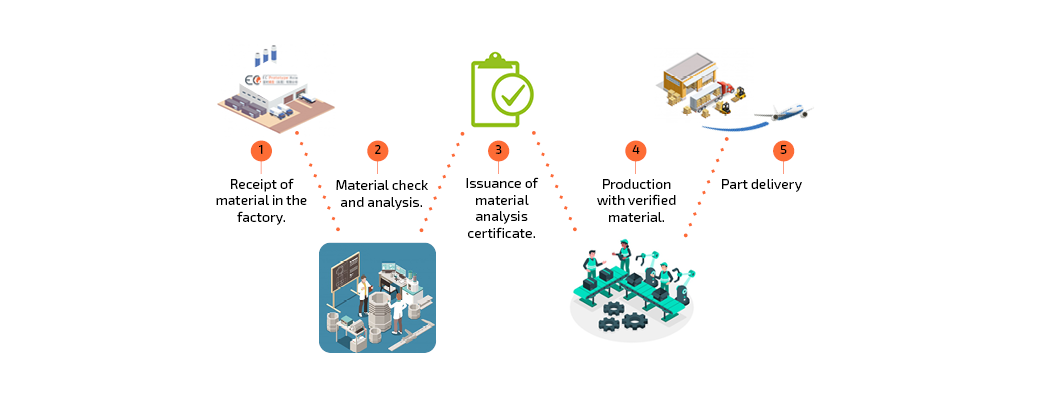

To guarantee the use of the requested materials, we are equipped with the latest generation of metal and plastic analysis machines.

Our material analysis machines:

In order to guarantee that the parts produced comply with your requirements in terms of surface quality and treatment, our quality control department focuses on:

Our machinery & tools:

We attach great importance to the conformity of your parts and make it a point of honour to carry out rigorous checks at various stages of production. This allows us to quickly identify any non-conformities and correct them before your parts are shipped. As a result of these checks, we are able to issue certificates of conformity (CCPU 2.1; 2.2 and 3.1) for low-volume production.